Wordless Wednesday will be on a one month break.

Spice Of Life! continues unabated with the April AtoZ Challenge.

Take Care!

A khatta-meetha take on life around me through my presbiopic eyes!

|

| First roasting |

So does one simply break open the shell to get the nuts? No.. Far from it. These drupes undergo their first roasting over steam to mark the start of processing.

|

| Following first roasting |

The drupes are put into special machines that cut open the hard outer shell. Earlier, the cutting was done manually which did horrible things to the hands of the ladies doing this delicate job. The machine we saw, picked up one drupe at a time, split the cover and the broken cover and kernel were ejected out. This shell has toxic substances (which cause terrible reactions when in contact with skin) and our guide cautioned us against touching them.

|

| Machine to cut the shell open |

|

| The machine ‘ingests’ and cuts one drupe at a time |

|

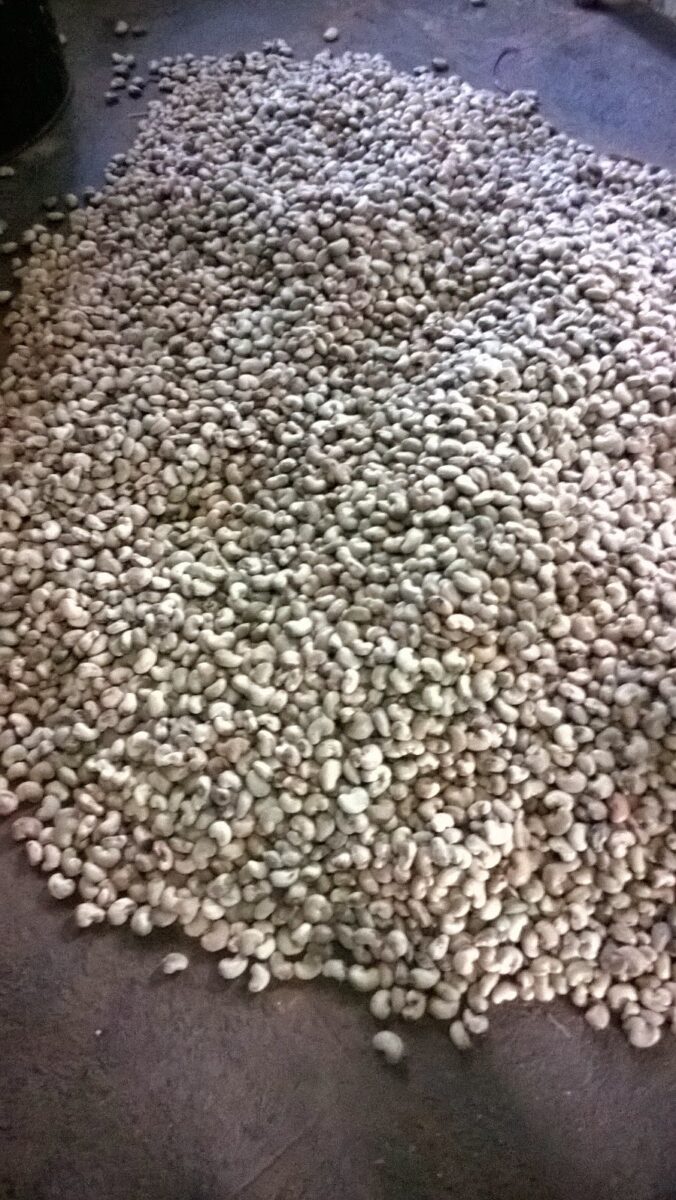

| Shells and kernels |

Shells are

sold to paint making companies and the kernels are roasted for a second

time. The resultant product is covered in a dry thin brown skin which may be

removed by further processing. Some kernels are sold with these brown

skins itself.

The kernels are now ready for sorting. This process is done by skilled hands and eyes that segregate the nuts based on their size and colour. I witnessed one lady who sat at a ‘console’ (see image below) and went about deftly throwing cashews in separate containers without even looking up from the pile in front of her.

What Aim! There was no scope for mistakes.

|

| The kernels on the table are put into the tins around it based on their size, shape |

|

| Separated and Packed |

Grading cashew kernels is important as the bigger ones are priced higher. The broken pieces are sold as such and are ideal for adding to cakes or sauces. At a cashew shop one finds them graded asW150, W180. W210, W240 and so on. W refers to whole (B will stand for broken; S for split etc) and the digits are number of kernels per pound. So W150 means there would be 150 kernels per pound. There is a category called SW which means Scorched Wholes where the kernels are scorched or marginally darkened due to excessive roasting. Here is a link with some info about cashew grades.

|

| At the sales counter |

The entire process may take a week or more. I was told that despite widespread cultivation of cashews in the coastal regions, many factories process nuts imported from South America (they are cheaper despite travelling across the oceans) compared to the local produce. Ironic isn’t it?

Other factories may have different processing methods but the general idea is to dry, crack open the drupes, roast and then segregate them. Some are further processed into salted cashews or flavoured with other spices.

Here another two images from the factory.

|

| An old manual shell cutting machine |

|

| Packed discarded cashew shells ready to be sent to paint makers |

Point to note: There are several cashew factories in Goa but not all welcome visitors. We took a chance with this one and got lucky.

Even at this stage in life, I have learnt something new. Learning never ends… We just need to have an open and curious mind…

Ciao folks!

|

| Lovely ripe mangos fill the air with their intoxicatingly sweet fragrance that is sure to tempt passerbys to buy them. |

It is widely known that fruit that is available in earlier months may be artificially ripened using various techniques. That obviously prevents the real flavour from developing. Reports state that Carbide is often used to ripen mangoes. Since they are available much before their natural ripenening period, they are obviously very costly and yet do not taste like the real thing.

So how do we know?

|

| Check the curve on the mango. It must be a gentle curve and not a deep depression |

There are still few more days for the Alphonso season. Thereafter there are many other varieties each with it a unique flavour. Try them and continue to enjoy the fruit at its natural peak season.

Enjoy!

Popularly called “Main Street” it retains its olde world charm, as almost all establishments take the mandatory Puneri afternoon siesta… Malls or not, these shops are shut every afternoon and the weekly off continues to be Sunday instead of Monday like most other shops in the city. Some of the shops will take you back in time to the British era with their quaint wooden panelling, wooden steps and decor of an age gone by.

Marzorin is one such cafe (if we can call it so) housed in a building that can easily be from the last century. Its biggest claim to fame are its sandwiches.While I dont much relish their mayonnaise, there are those who will sing its praises. What I love best are their macaroons- the almond ones. Buying those had become an annual ritual for us when we came from our distant bases. Their taste is unchanged over the years but size certainly has reduced.

|

| Enjoy the view on the bustling street |

|

| Almond macaroons |

Marzorin is a great place to just sit down and soak in the atmosphere of this road. The Pasteur bakery next door also offers reasonably priced cakes but if you are looking for exclusive gourment stuff, you better look elsewhere. Budhani located just across the street shows is known far and wide for its Batata chivda (a savoury snack made from fried potato strips). These are just a few places on a foodie trail on the Main Street- one that demands you to first tear up your calorie chart!

Cheers!